DECREASE CARBON FOOTPRINT + INCREASE QUALITY WITH LOCAL VINYL PRESSING

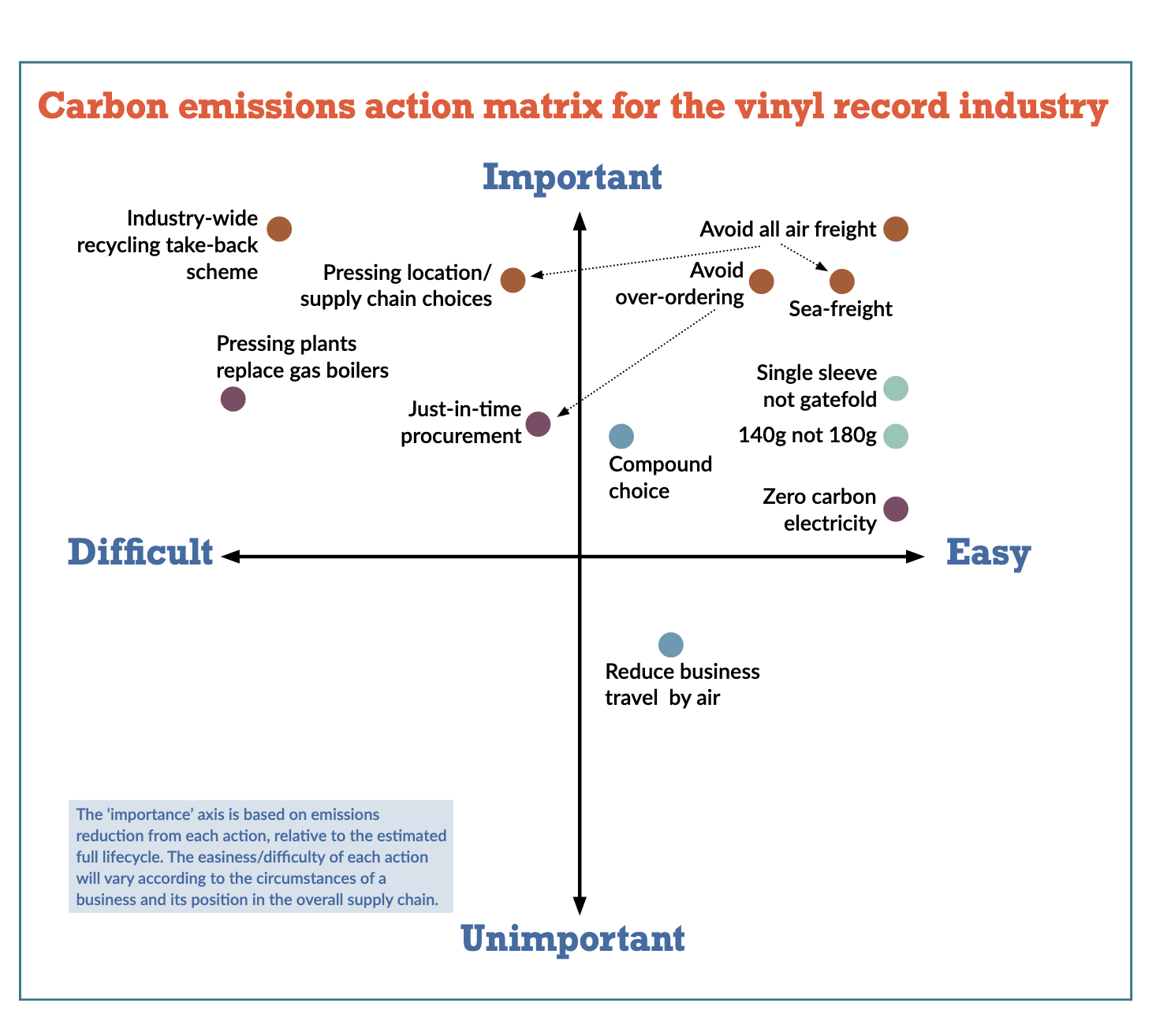

The Vinyl Record Manufacturers’ Association (VRMA) recently released its Second Carbon Footprinting Report for the Vinyl Record Industry. Aimed at reducing carbon emissions in the vinyl record supply chain, it concludes that employing the services of local and regional vinyl presses is critical to sustainability.

“Pressing locally in each major market that the record is being released in not only eliminates air freight emissions, but can also improve speed-to-market,” the report reveals. “This procurement strategy also dovetails nicely with a just-in-time approach, which can greatly reduce the risk of over-ordering.”

More reasons to press locally, according to Paul Rigby of Zenith Records and Steve Lynch of Program Records (both in Australia) in a What Hi Fi? feature: “We love being able to press records from our local scene; there is something extra special about pressing records for bands/people you know,” says Lynch, who also acknowledges that choosing a local pressing plant “supports local jobs, fosters a sense of community, and helps build a robust ecosystem for music creation.”

Here at Citizen Vinyl, our press operators are also active members of the local music scene, so we get it.

Rigby and Lynch recognize several benefits of staying local for the artists, too. “Local plants offer faster turnaround times,” says Lynch. “Artists and labels are also able to come and visit us when we have a test pressing or their records ready for them. This means they can get their records to the listener and onto store shelves more quickly."

“Staying local also allows artists and labels to have more direct oversight and control over the production process. They can visit the pressing plant and communicate face-to-face with us.”

Back to creating a smaller carbon footprint: The Vinyl Record Manufacturers’ Association notes “smaller emission reductions that are available at the manufacturing stage [include] choice of compound [such as Bio-Vinyl, see below], minimizing print packaging (especially avoiding gatefolds for single albums), and pressing on 140g rather than 180g.